Welcome to our Reality Capture FAQ page!

Here, we’ve compiled answers to the most common questions about our services, including 3D laser scanning, digital twin technologies, 3D modeling for BIM, and facility management solutions. Whether you're new to reality capture or looking to learn more about how our technologies can improve your operations, you’ll find helpful information here. If you don't find the answer to your question, feel free to contact us for further assistance.

Laser Scanning: FAQs

Laser scanning is a method of Reality Capture using lasers to efficiently digitize 3-dimensional data on the surface of an object or environment without touching what is being measured, much like a 360-degree photo, but with an accurate position on every individual pixel.

Laser scanning offers a quicker, more reliable way to capture detailed, real-world data. This technology is revolutionizing how we design, manage, and maintain assets, providing more accurate documentation and reducing the risks associated with manual measurements.

Laser scanning is a method of Reality Capture that uses LiDAR technology (Light Detection and Ranging) to digitally capture 3D data of an object or environment. Unlike traditional methods, laser scanning is like taking a 360-degree photo, but instead of just capturing an image, it records precise measurements (x, y, z) for every point, creating a detailed 3D "point cloud" made up of millions of data points. This enables professionals to obtain an accurate, geometric representation of the scene in a fraction of the time it would take with traditional methods.

Laser scanning provides you with accurate, reliable 3D data that saves time, reduces errors, and improves the overall quality of your project documentation. Whether for design, analysis, or planning, this technology enhances decision-making and ensures you have the most precise information to work with.

Common applications of laser scanning include:

- Renovation/Refurbishment of current conditions

- Heritage documentation for historical preservation

- Construction projects:

- check quality assurance (change and clash detection with BIMs)

- capture progress milestones

- perform completed work assessments

- create as-builts for facilities management

- Infrastructure – roads, rail, bridges, and tunnels

- Plant & facility management – oil, gas, refineries, and pipelines

- Topographical surveys

- Calculating volumes, clearances, and deviation analysis

- Floor slab mapping and flatness reporting

- Accident scene reconstruction

- Hazardous or hard-to-reach surveys

- Prefabrication and reverse engineering

Speed

A single laser scanner can capture millions of 3D data points per second, providing intricate detail of every aspect of your project in a fraction of the time taken by conventional methods.

Accuracy

Remove uncertainty and greatly reduce project liability with comprehensive spatial and visual accuracies previously unachievable.

Persuasive

Incorporating a laser scan into the design of your project assures more efficient and accurate communication promoting faster decision making and enlightened team collaboration.

Economical

Never miss a measurement again. A 3D laser scan will capture complete detail reducing or even eliminating the need to return to the project site to answer unanticipated questions.

Non-intrusive

Eliminate or minimize operational shut-down times and client inconvenience with rapid data acquisition.

Safe

Scanning is a touchless technology normally completed safely from the ground without the need for harnesses, lifts or cranes. Measurements can be obtained remotely in hard to reach or hazardous locations keeping workers out of harm’s way.

3D laser scanning in construction is a cutting-edge technology used to capture accurate 3D data of a building or construction site. For construction professionals, 3D laser scanning provides an accurate, real-time view of the site or building, allowing for better planning, design, and decision-making. It helps in documenting existing conditions, verifying designs, detecting clashes in plans, and reducing costly errors. Whether for renovations, retrofits, or new builds, it improves project efficiency and ensures better outcomes from start to finish.

BIM FAQs

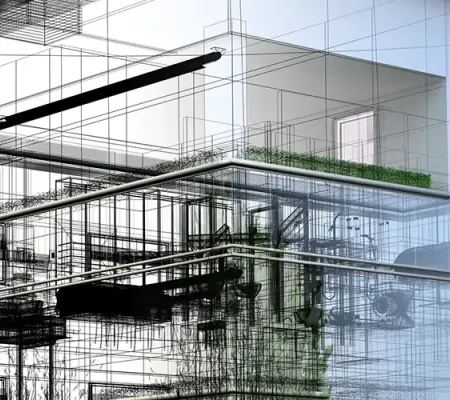

Building Information Modeling (BIM) is a process that uses advanced tools and technologies to create and manage digital representations of the physical and functional characteristics of a building or infrastructure. BIM provides a comprehensive approach to planning, designing, constructing, and managing buildings, improving collaboration and efficiency throughout the entire project lifecycle. This section will answer your key questions about BIM, helping you understand how it can streamline workflows, enhance decision-making, and optimize project outcomes.

Building Information Modelling (BIM) is a process supported by various tools and technologies involving the generation and management of digital representations of physical and functional characteristics of places. Building Information Models (BIMs) are files (often but not always in proprietary formats and containing proprietary data) which can be extracted, exchanged or networked to support decision-making regarding a built asset. -Wikipedia

The term “Scan to BIM” refers to the process of digitally capturing a physical space or site, from the ground and from the air, to create an accurate 3D representation of its current state. That representation can then be used by building design and construction professionals as a reliable source of truth about their project environment.

When speaking about Level of Development (LOD), we refer to the BIM Forum definitions*: “The Level of Development (LOD) Specification is a reference that enables practitioners in the AEC Industry to specify and articulate with a high level of clarity the content and reliability of Building Information Models (BIMs) at various stages in the design and construction process."

In the Reality Capture ecosystem, we typically reference LOD 500*: “LOD 500 does not indicate a higher level than LOD 400, rather it indicates that the model element’s geometry is determined through observation of an existing item rather than design of a future item. The LOD 500 definition requires that the model element’s accuracy be specified…”

SDMM uses their own Level of Accuracy (LOA) Specification document to facilitate client conversations when determining the scope of work for modelling projects.

* BIM Forum

“Level of Accuracy (LOA) Specification is a reference or guideline that enables Professionals in the Architectural, Engineering, Construction, Owner (AECO) Industry to specify and articulate with clarity, the accuracy and means by which to represent and document existing conditions. The intent of the Specification is to provide a framework for the AECO industry to establish standards and consistency in Building Documentation so that those employing it will more likely achieve the accuracy results they require.” - US Institute of Building Documentation.

To accomplish this, we employ our Level of Accuracy (LOA) Specification document, which is nothing more than a simplified graphical chart that helps industry professionals visually select and communicate what they require for their existing condition documentation requirements. This provides architects and engineers with a mechanism to set their expectations for a 3-D model deliverable, like Autodesk Revit for example. Working through this at the outset of every modelling project provides assurances to both SDMM and their customers for a successful project outcome.

Digital Twins FAQs

Digital twins are revolutionizing industries by creating virtual replicas of physical assets or systems. In fields like construction, manufacturing, and facility management, the ability to monitor and analyze real-world conditions in real time offers unprecedented benefits. However, understanding how digital twins work and how they can be applied to your projects may not always be straightforward. In this section, we’ll answer the most common questions about digital twins, explaining how they can transform your business operations, improve efficiency, and reduce costs by integrating real-time data into every stage of the asset lifecycle.

A digital twin is a virtual replica of a physical object, system, or building. It is created using data from 3D laser scanning, photogrammetric sensors, and other data sources to monitor, simulate, and analyze the physical counterpart in real time.

Digital twins allow for real-time monitoring, predictive maintenance, efficient facility management, and data-driven decision-making. They improve asset performance, reduce downtime, and enable more effective planning and analysis. SDMM provides visual digital twins derived from 3D laser scanning and photogrammetry workflows in the form of point clouds and texturized meshes. These outputs become the foundation for detailed CAD plans and 3D models. What’s more, these workflows also deliver high resolution imagery in the form of 360° virtual walkthroughs giving end users unparalleled visibility of their project environments. This eliminates the need for repeated visits to the project site with 24/7 remote access and improves communication for all stakeholders.

Digital twins are highly accurate, as they are created from precise 3D measured data, photo sensor inputs, and real-world data streams. This provides a comprehensive representation of the physical environment, ensuring accuracy in monitoring and decision-making.

Digital twins are used across various industries, including construction, real estate, facility management, manufacturing, energy, healthcare, infrastructure and heritage sites. They are valuable for managing and maintaining both physical and operational assets.

As-Built Drawings FAQs

As-built drawings are critical for accurately reflecting the final construction of a building or project. These drawings capture all the changes made during construction, including modifications, updates, and any deviations from the original design. As-built drawings serve as the official record of the completed structure, ensuring that future renovations, maintenance, or repairs are based on the most current information. In this section, we’ll answer common questions about as-built drawings and explain how they help streamline future projects, improve facility management, and support long-term maintenance planning.

As-built drawings differ from design plans as they reflect the actual built environment, accounting for any deviations, modifications, or changes that occurred during construction. They provide a more accurate representation of the completed structure. SDMM likes to refer to these as Existing Condition Drawings.

As-built drawings differ from design plans as they reflect the actual built environment, accounting for any deviations, modifications, or changes that occurred during construction. They provide a more accurate representation of the completed structure. SDMM likes to refer to these as Existing Condition Drawings.

As-built drawings are essential for future renovations, facility management, and any design or construction modifications. They serve as the official record of the completed structure, helping teams make informed decisions during future projects. Unfortunately, in most cases, as-built drawings are never completed properly and do not always reflect the final constructed state. For this reason, reality capture is the smart play to capture the existing condition of your project site during the early phases of planning and design. We discuss the issue further in the blog post about the importance of existing conditions drawings.

As-built drawings generated from Reality Capture workflows are very reliable. They are created using 3D laser scanning point cloud data, 3D imagery, and manual measurements to capture the exact dimensions and configurations of the building. This data is then converted into accurate, detailed drawings in CAD or BIM formats.

As-built drawings provide facilities teams with an accurate reference for maintaining the building. They help manage assets, plan for repairs or upgrades, and ensure that any changes to the building's systems or layout are documented for future reference.

Contact Us for Expert Reality Capture Solutions

Need 3D laser scanning services, BIM modeling, or digital twin consulting? Contact us today to discuss your project and learn how our cutting-edge reality capture solutions can streamline your workflow!